扬兴科技

企业

扬兴科技

企业

森木磊石

企业

森木磊石

企业

ICer消食片

ICer消食片

工程师看海

专栏

工程师看海

专栏

Felix分析

专栏

Felix分析

专栏

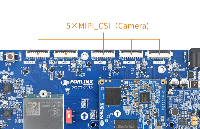

飞凌嵌入式

企业

飞凌嵌入式

企业

花茶晶晶

专栏

花茶晶晶

专栏

经纬恒润

企业

经纬恒润

企业

亿佰特物联网应用专家

企业

亿佰特物联网应用专家

企业

eeDesigner

专栏

eeDesigner

专栏

Felix分析

专栏

Felix分析

专栏

电子发烧友网官方

电子发烧友网官方

电子发烧友网官方

电子发烧友网官方

章鹰观察

专栏

章鹰观察

专栏

Monika观察

专栏

Monika观察

专栏

Simon观察

专栏

Simon观察

专栏

Simon观察

专栏

Simon观察

专栏

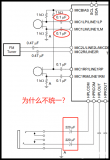

北汇信息POLELINK

企业

北汇信息POLELINK

企业

jf_74264200

jf_74264200