查看陶瓷电容器时常见的问题是温度系数数字/字母是什么意思?

这些数字通常会分解到温度范围和电容在该特定范围内的变化。

您需要了解的第一件事就是您正在考虑的标准和课程。

这些由国际电工委员会(IEC)和

电子工业联盟(EIA)分开

这是一个关于不同类和定义的图表:

IEC / EN 603841&

IEC / EN 60384-8 / 9/21/22

EIA RS-198

1类陶瓷电容器为谐振

威廉希尔官方网站

应用提供高稳定性和低损耗

I类陶瓷帽为谐振威廉希尔官方网站

应用提供高稳定性和低损耗

2类陶瓷电容器具有高容积效率,适用于平滑,旁路,耦合和去耦应用

II类(或写入2级)陶瓷电容器具有高容积效率,电容变化低于-15%至+ 15%,温度范围高于-55°C至+ 125°C,用于平滑,旁路,

耦合和去耦应用

3类陶瓷电容器是阻挡层电容器,不再标准化

III类(或写入3级)陶瓷电容器的容积效率高于EIA II级,在10°C至55°C的较低温度范围内,电容的典型变化为-22%至+ 56%。

它们可以用EIA级2- Y5U / Y5V或Z5U / Z5V电容代替

IV类(或写入类4)陶瓷电容器是阻挡层电容器,不再标准化

通过理解类定义,您可以了解温度系数如何分解。

每个EIA-RS-198的1级

温度系数α10-6/ K字母代码

温度系数的乘数数字代码

容差温度系数字母代码

C:0.0

0:-1

G:±30

B:0.3

1:-10

H±60

L:0.8

2:-100

J:±120

答:0.9

3:-1000

K:±250

M:1.0

4:+1

L:±500

P:1.5

6:+10

M:±1000

R:2.2

7:+100

N:±2500

S:3.3

8:+1000

T:4.7

V:5.6

你:7.5

符合IEC / EN 60384-8 / 21和EIA-RS-198的1级

陶瓷名称

温度系数α10-6/ K.

α-Tolerance 10-6 / K.

子类

IEC / EN-字母代码

EIA字母代码

P100

100

±30

1B

AG

M7G

NP0

0

±30

1B

CG

C0G

N33

-33

±30

1B

HG

H2G

N75

-75

±30

1B

LG

L2G

N150

-150

±60

1B

PH

P2H

N220

-220

±60

1B

RH

R2H

N330

-330

±60

1B

SH

S2H

N470

-470

±60

1B

TH

T2H

N750

-750

±120

1B

UJ

U2J

N1000

-1000

±250

1F

QK

Q3K

N1500

-1500

±250

1F

VK

P3K

看一下这些图表,带有EIA代码“C0G”的“NP0”电容将具有0漂移,公差为±30 ppm / K,而代码为“P3K”的“N1500”将具有-1500 ppm /

K漂移,最大公差为±250 ppm /°C。

请注意,IEC和EIA电容器代码是工业电容器代码,与军用电容器代码不同。

每个EIA RS-198的2级

低温字母代码

高温数字代码

在温度范围内改变电容的字母代码

X = -55°C(-67°F)

4 = + 65°C(+ 149°F)

P =±10%

Y = -30°C(-22°F)

5 = + 85°C(+ 185°F)

R =±15%

Z = + 10°C(+ 50°F)

6 = + 105°C(+ 221°F)

S =±22%

7 = + 125°C(+ 257°F(华氏度))

T = + 22 / -33%

8 = + 150°C(+ 302°F)

U = + 22 / -56%

9 = + 200°C(+ 392°F)

V = + 22 / -82%

例如,Z5U电容器的工作温度范围为+ 10°C至+ 85°C,电容变化最多为+ 22%至-56%。

X7R电容器的工作温度范围为-55°C至+ 125°C,电容变化最大为±15%。

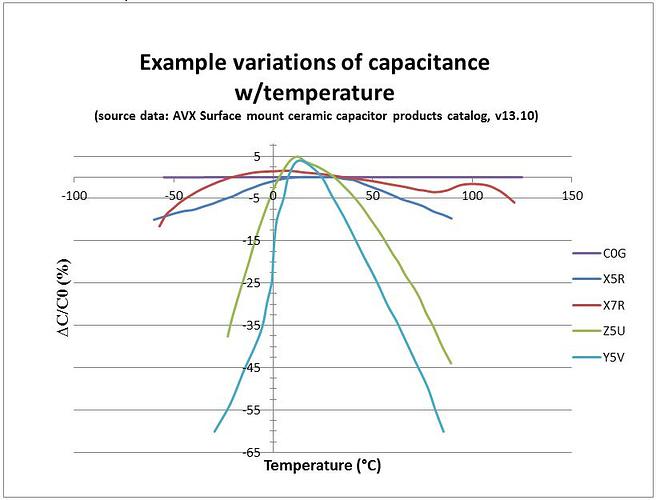

以下是一些常见的Class 2配置:

X8R(-55 / + 150,ΔC/ C0 =±15%),

X7R(-55 / + 125°C,ΔC/ C0 =±15%),

X6R(-55 / + 105°C,ΔC/ C0 =±15%),

X5R(-55 / + 85°C,ΔC/ C0 =±15%),

X7S(-55 / + 125,ΔC/ C0 =±22%),

Z5U(+ 10 / + 85°C,ΔC/ C0 = + 22 / -56%),

Y5V(-30 / + 85°C,ΔC/ C0 = + 22 / -82%),

符合IEC / EN 60384-9 / 22的2级

电容变化代码

U = 0时的最大电容变化ΔC/ C0

U = UN时的最大电容变化ΔC/ C0

温度范围代码

温度范围

2B

±10%

+ 10 / -15%

1

-55 ... + 125°C

2C

±20%

+ 20 / -30%

2

-55 ... + 85°C

2D

+ 20 / -30%

+ 20 / -40%

3

-40 ... + 85°C

2E

+ 22 / -56%

+ 22 / -70%

4

-25 ... + 85°C

2F

+ 30 / -80%

+ 30 / -90%

五

(-10 ... +70)°C

2R

±15%

-

6

+10 ... + 85°C

2X

±15%

+ 15 / -25%

-

-

在某些情况下,可以将EIA代码转换为IEC / EN代码。

可能会发生轻微变化,但通常是可以容忍的。

X7R与2X1相关

Z5U与2E6相关

Y5V类似于2F4,像差:ΔC/ C0 = + 30 / -80%而不是+ 30 / -82%

X7S类似于2C1,像差:ΔC/ C0 =±20%而不是±22%

X8R没有IEC / EN代码可用

以上来自于谷歌翻译

以下为原文

A common ques

tion when looking at ceramic capacitors is what do the temperature coefficient numbers/letters mean? These numbers will generally break down to a temperature range and the variation in capacitance over that specific range. The first thing you need to understand with what standard and class you are looking at. These are split between the International Electrotechnical Commission (IEC) and the Electronic Industries Alliance (EIA)

Here is a chart on the different classes and definitions:

[tr]IEC/EN 603841 &

IEC/EN 60384-8/9/21/22EIA RS-198[/tr]

| Class 1 ceramic caps offer high stability and low losses for resonant circuit applications | Class I ceramic caps offer high stability and low losses for resonant circuit applications |

| Class 2 ceramic capacitors offer high volumetric efficiency for smoothing, by-pass, coupling and decoupling applications | Class II (or written class 2) ceramic capacitors offer high volumetric efficiency with change of capacitance lower than −15% to +15% and a temperature range greater than −55 °C to +125 °C, for smoothing, by-pass, coupling and decoupling applications |

| Class 3 ceramic capacitors are barrier layer capacitors which are not standardized anymore | Class III (or written class 3) ceramic capacitors offer higher volumetric efficiency than EIA class II and typical change of capacitance by −22% to +56% over a lower temperature range of 10 °C to 55 °C. They can be substituted with EIA class 2- Y5U/Y5V or Z5U/Z5V capacitors |

| Class IV (or written class 4) ceramic capacitors are barrier layer capacitors which are not standardized anymore |

With class definitions understood you can look how the temperature coefficients break down.

Class 1 per EIA-RS-198

[tr]Temperature coefficient α

10-6 /K Letter codeMultiplier of the temperature

coefficient Number codeTolerance of the temperature

coefficient Letter code[/tr]

| C: 0.0 | 0: -1 | G: ± 30 |

| B: 0.3 | 1: -10 | H ± 60 |

| L: 0.8 | 2: −100 | J: ±120 |

| A: 0.9 | 3: −1000 | K: ±250 |

| M: 1.0 | 4: +1 | L: ±500 |

| P: 1.5 | 6: +10 | M: ±1000 |

| R: 2.2 | 7: +100 | N: ±2500 |

| S: 3.3 | 8: +1000 | |

| T: 4.7 | | |

| V: 5.6 | | |

| U: 7.5 | | |

Class 1 per IEC/EN 60384-8/21 and EIA-RS-198

[tr]Ceramic namesTemperature coefficient α 10-6 /Kα-Tolerance 10-6 /KSub-classIEC/ EN- letter codeEIA letter code[/tr]

| P100 | 100 | ±30 | 1B | AG | M7G |

| NP0 | 0 | ±30 | 1B | CG | C0G |

| N33 | −33 | ±30 | 1B | HG | H2G |

| N75 | −75 | ±30 | 1B | LG | L2G |

| N150 | −150 | ±60 | 1B | PH | P2H |

| N220 | −220 | ±60 | 1B | RH | R2H |

| N330 | −330 | ±60 | 1B | SH | S2H |

| N470 | −470 | ±60 | 1B | TH | T2H |

| N750 | −750 | ±120 | 1B | UJ | U2J |

| N1000 | −1000 | ±250 | 1F | QK | Q3K |

| N1500 | −1500 | ±250 | 1F | VK | P3K |

Looking at these charts you see, an “NP0” capacitor with EIA code “C0G” will have 0 drift, with a tolerance of ±30 ppm/K, while an “N1500” with the code “P3K” will have −1500 ppm/K drift, with a maximum tolerance of ±250 ppm/°C.

Note that the IEC and EIA capacitor codes are industry capacitor codes and not the same as military capacitor codes.

Class 2 per EIA RS-198

[tr]Letter Code for Low TempNumber Code for High TempLetter code for change of capacitance

over the temp range[/tr]

| X = −55 °C (−67 °F) | 4 = +65 °C (+149 °F) | P = ±10% |

| Y = −30 °C (−22 °F) | 5 = +85 °C (+185 °F) | R = ±15% |

| Z = +10 °C (+50 °F) | 6 = +105 °C (+221 °F) | S = ±22% |

| 7 = +125 °C (+257 °F) | T = +22/−33% |

| 8 = +150 °C (+302 °F) | U = +22/−56% |

| 9 = +200 °C (+392 °F) | V = +22/−82% |

For instance, a Z5U capacitor will operate from +10 °C to +85 °C with a capacitance change of at most +22% to −56%. An X7R capacitor will operate from −55 °C to +125 °C with a capacitance change of at most ±15%.

Here are some common Class 2 configurations:

- X8R (−55/+150, ΔC/C0 = ±15%),

- X7R (−55/+125 °C, ΔC/C0 = ±15%),

- X6R (−55/+105 °C, ΔC/C0 = ±15%),

- X5R (−55/+85 °C, ΔC/C0 = ±15%),

- X7S (−55/+125, ΔC/C0 = ±22%),

- Z5U (+10/+85 °C, ΔC/C0 = +22/−56%),

- Y5V (−30/+85 °C, ΔC/C0 = +22/−82%),

Class 2 per IEC/EN 60384-9/22

[tr]Code for capacitance changeMax capacitance change

ΔC/C0 at U = 0Max capacitance

change

ΔC/C0 at U = UNCode for temp rangeTemp Range[/tr]

| 2B | ±10% | +10/−15% | 1 | −55 … +125 °C |

| 2C | ±20% | +20/−30% | 2 | −55 … +85 °C |

| 2D | +20/−30% | +20/−40% | 3 | −40 … +85 °C |

| 2E | +22/−56% | +22/−70% | 4 | −25 … +85 °C |

| 2F | +30/−80% | +30/−90% | 5 | (-10 … +70) °C |

| 2R | ±15% | − | 6 | +10 … +85 °C |

| 2X | ±15% | +15/−25% | - | - |

In some cases it is possible to translate the EIA code into the IEC/EN code. Slight variations can occur, but normally are tolerable.

- X7R correlates with 2X1

- Z5U correlates with 2E6

- Y5V similar to 2F4, aberration: ΔC/C0 = +30/−80% instead of +30/−82%

- X7S similar to 2C1, aberration: ΔC/C0 = ±20% instead of ±22%

- X8R no IEC/EN code available

举报

举报

举报

举报

举报

举报